Beskrivelse af flexo trykmaskiner

Description of flexo presses

Flexo presses prints on flexible packaging applications and labels. The method results in high quality printed material such as polyester, OPP, nylon, and PE. Furthermore, the CI flexo printer can press papers, carton board, non-woven textiles, coated or un-coated liner board. The presses efficiently produces large rolls of the printed web. After printing, slitting machines can slit the plastic film or paper into the finished size. Typical end products could be retail and shopping bags, food and hygiene bags and sacks. Other kinds of products and materials could be milk and beverage cartons, paper products, wallpaper and much more.

Moreover, a flexographic press uses a wide range of inks that are with low viscosity and very often water based, and it is perfect to print on many materials. This type of ink means faster drying and printing.

3 types of flexographic presses

There are 3 general press types, which are CI flexographic presses, Stack flexographic presses and In-line flexo presses.

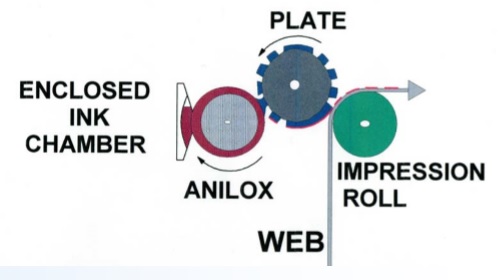

The printing itself can be illustrated this way: The anilox roller ensures that the ink is transferred to the flexible plate and from there press on the web.

Printing unit illustrated.

Anilox roller ensures that the ink is transferred to the plate or cliché and there from press on the web. A printing unit, usually consists of anilox rollers, plate cylinder, impression cylinder, and inking system. A scraber can be mounted on the anilox roll. It can also called a doctor blade system. This can be used to take way excess color. The illustration describes the process for all 3 types of presses, but the setup differ.

CI Flexo printing – main characteristics

The main characteristic regarding Central impression flexographic presses is that all printing units is arranged around a central drum. Here is a photo of an 8 color printer. it can print on PE, PP, OPP, PET, Paper. As it can be seen from the photo the printing units surrounds the drum. This type of press offers a high print quality and registration accuracy. Registration accuracy is when the ink combinations is aligned precisely on the substrate.

CI flexo press – Central Drum from the outside – Printing units on each side and around.

Stack flexo press – main characteristics

Stack presses has the printing units stacked one above the other. Therefore, each station has its own impression roll, whereas the central impression in contrary has the central drum. The photo shows a 6 color stack press. Furthermore, the photo shows how the printing units are stacked above each other. Euro Machinery buy and sell both stand alone out off line stack flexo presses and stack flexo presses that are in-line with e.g. extruders or bag machines. Stack presses can print on both sides of the substrate. The presses are also best for small lots.

This is a photo of a stack flexo press, half of the printing units are visible.

In-line flexo presses – main characteristics

In-line flexo presses has the printing units laid out in a horizontal line. These type of presses are usually suited for more narrow webs, compared to CI flexo presses.

Horizontal positioning of printing units.

Lastly, all the printers have an unwind and infeed section, printing units, drying system, and a rewind and outfeed section.

How can Euro Machinery help in finding the right machine?

We hope that our blog gives a short introduction and small understanding of flexographic printing machines in general. Furtermore, Euro Machinery ApS can help to find the right press, and we have in our data base of machines many types of machines.

Take a look on our CI flexo presses here

See our Stack flexo in-line presses here

Check out Stack flexo stand-alone presses here

In conclusion, our company has sold flexographic presses worldwide therefore we can also help you to find the right press. If you would like to buy or sell machines, please contact us.